On March 5th, the Foshan Federation of Industry and Commerce held a symposium on "How to Empower the Beijiao Home Appliance Cluster with Industrial Internet and Industrial Design". Leaders such as Zhou Xu, a member of the Shunde District Standing Committee, Wu Xianqiang, Director of the Shunde District Economic Promotion Bureau, and Yu Hongping, Secretary General of the Foshan Federation of Industry and Commerce, attended the symposium. At the same time, renowned economist and Professor Zhou Qiren from the National Development Research Institute of Peking University were specially invited to the site for guidance. As a representative of a technology enterprise, SiE Information was invited to participate in the conference and share the theme. On site government leaders, experts, scholars, and corporate guests gathered to discuss how industrial design and industrial internet service providers can drive the optimization and upgrading of Shunde Beijiao home appliance cluster.

Shunde Beijiao is an important town in China's home appliance manufacturing industry. As one of the world-class home appliance production bases, it has the world's largest and most complete white appliance industry chain and small appliance industry cluster. The output value of the home appliance manufacturing industry has exceeded 100 billion yuan, accounting for about 10% of the total output value of the national home appliance industry. The home appliance industry cluster needs to undergo digital transformation and upgrading to achieve high-quality development of the manufacturing industry, "Professor Zhou Qiren pointed out, Digital technology is an important means to promote the transformation of the economy from high speed to high quality. Digitalization must have a mainstay, and industrial enterprises must be customer-centric and employee centered in digitalization. Productive service enterprises should continue to pay attention and understand how to spend money to purchase professional services, in order to make enterprises stronger

How can Shunde's home appliance industry cluster achieve high-quality development in the wave of "intelligent manufacturing" in China? Faced with the pressure of the cost curve, how can home appliance manufacturing enterprises use "digitization" to break through? At the meeting, Zhang Zhen, Vice President of SiE Information Industry Center, discussed the difficulties and breakthroughs in the digital transformation of the home appliance industry with everyone through case sharing.

The home appliance industry is one of the key industries for SiE Information to layout and expand. With the maturity and development of the market economy, the home appliance industry has shown characteristics such as faster changes in order demand, diversified categories, small batch orders, and an increasing number of fast cycles. Therefore, a production and manufacturing system that can shorten the product lifecycle, strictly control the production process, improve product quality, reduce production costs, and adapt to future development needs is an important "weapon" for home appliance manufacturing enterprises to carry out digital transformation.

Through insight into the needs of customers in the home appliance industry, SiE Information has launched a customizable solution combining "omnichannel marketing+intelligent manufacturing+enterprise management", comprehensively covering the transformation needs of different types of home appliance enterprises. SiE Information assists TCL Electronics in customizing a digital chemical plant. Through SiE Information's independently developed manufacturing operation management platform SMOM, SiE Information optimizes the entire injection molding production process from manufacturing execution management, quality management, logistics management, mobiles management digital application, operation management, and other aspects. It establishes a central platform that can cover the entire manufacturing chain, achieving a 10% increase in overall manufacturing efficiency Reduced production losses by 10% and improved traceability accuracy to 99.9%; Collaborating with Panasonic Environment, from manufacturing execution system cooperation to the application and implementation of major modules such as production management, quality management, logistics management, equipment management, SCADA, etc., we have vertically broken through the barriers between Panasonic's various information systems, horizontally connected people, machines, materials, methods, and environments in the production process, and made data real-time and transparent, providing strong support for Panasonic Environment to consolidate its leading position in the industry, And while reducing personnel costs by nearly half, the output value is still steadily increasing, achieving the goal of reducing costs and increasing efficiency.

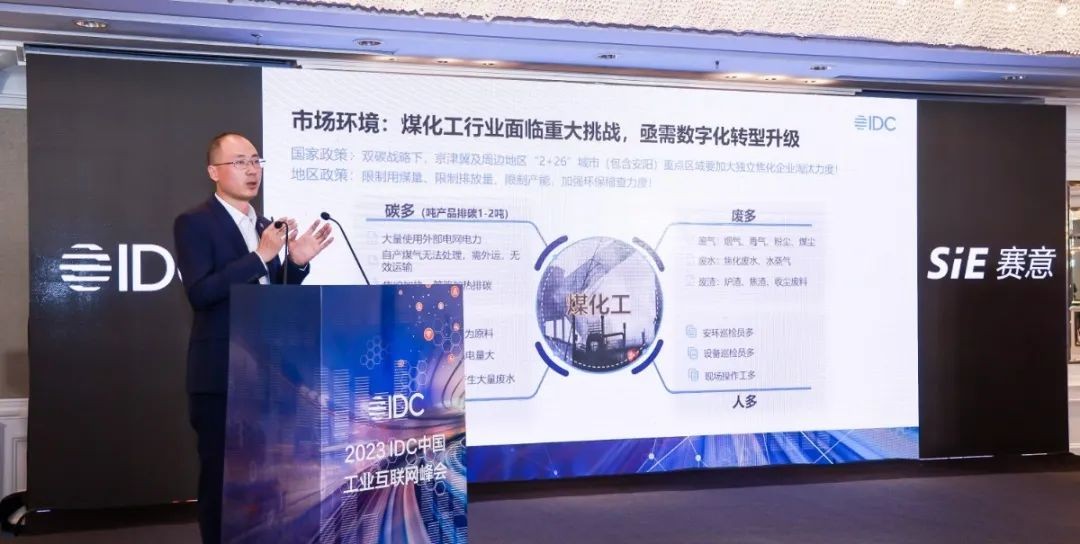

Enterprises in different industries may have different industry application scenarioses and needs when facing the proposition of "digital transformation". SiE Information is based on the transformation path of enterprise data capitalization and business integration, helping customers in different industries maximize data value, truly bringing digital transformation to enterprises, and empowering enterprise digital transformation.

In the recent 2021 government work report, it was clearly pointed out that: accelerate digital development, create new advantages in the digital economy, coordinate the promotion of digital industrialization and industrial digital transformation, and accelerate the pace of digital society construction. At present, digital technology is reshaping the business environment, and digitalization has become the key for enterprises to enhance their core competitiveness. As a digital empowerer for enterprises, SiE Information has been continuously cooperating with multiple industry leaders such as Midea, Huawei, Country Garden, Ping An, vivo, and Libai Group for 16 years, connecting upstream and downstream industries through digital empowering enterprises.